NiPro Optics has provided ophthalmic tooling to the the spectacle lens industry for more than twenty years. We fabricate Progressive, Bifocal, Blended, Aspheric, Toric, and Spherical designs to customer specfications.

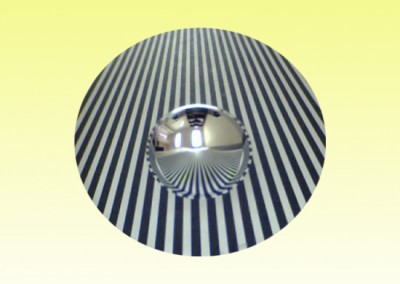

Using Single Point Diamond Turning, we bring the highest possible tooling precision to the lens manufacturer. Radius of curvature and other optical characteristics are controlled to “near perfect” geometry, leaving our customers maximum tolerances for their production process.

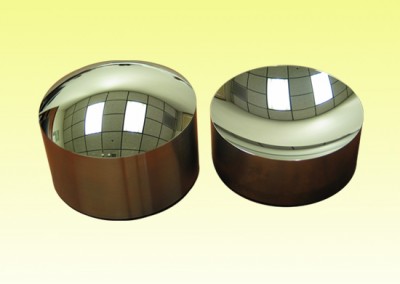

For polycarbonate, injection molding applications, we produce custom inserts. A steel or copper base is plated with high phosphorous nickel (Rockwell hardness of 50 C) and then diamond turned to the correct geometry. No post polish is required, eliminating all possibility of local aberrations.

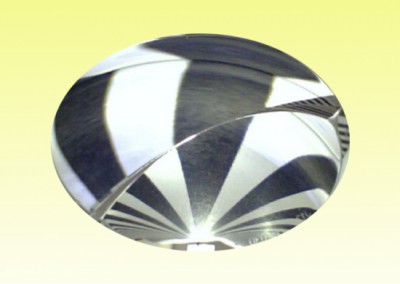

For use in casting operations, we also manufacture electroformed ophthalmic molds – ideal for cost effective replication of complex or intricate optical surfaces. Using customer supplied masters, or fabricating them ourselves through diamond turning, we produce nickel molds with the same characteristics as the replication tool.