Diamond Turned Optics

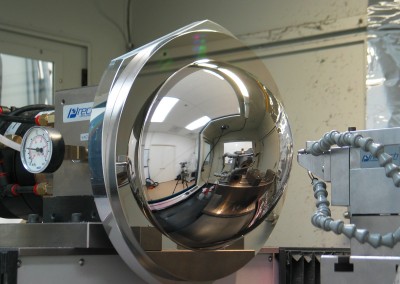

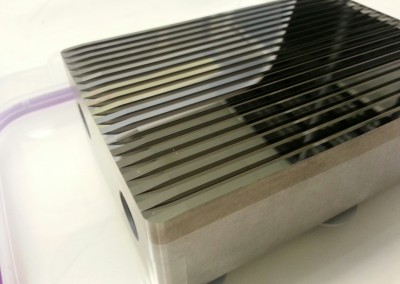

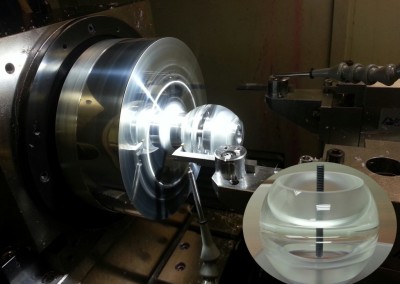

NiPro Optics uses single point diamond turning (SPDT) to produce optical components for full spectrum applications. We use 5 Axis capabilities with a slow servo option to produce complex coordinate geometries in a variety of plastics and metals. Typical projects for diamond turned optics include polygonal mirrors, reflectors, off axis parabolas, lens arrays, mold inserts, mandrels, and optical assemblies with many design parameters. Surfaces can be free form, aspheric, biconic, toric, fresnel, off-axis, and rotationally or non rotationally or non-rotationally symmetric.

Specializing in diamond turned metals, and dependent on part geometry, we often achieve surface roughness of less than 50 Angstroms RMS on aluminum substrates, and less than 30 Angstroms RMS on nickel, plated over metal substrates. Form accuracy on many components is better than 1/4 wave and often more precise.

To complete your project, we have coating designs to meet all performance and reflectivity requirements.